Carbon-containing fumes are one of the main substances damaging the environment and human health. Their negative effects are mitigated by catalysts that rely on platinum, palladium, and other expensive metals as their key components. With the support of the Russian Science Foundation, Tomsk State University chemists are working on new catalyst materials capable of neutralizing soot and carbon monoxide. They intend to use copper and silver as active components, which could help reduce the cost of the end product tenfold while preserving its efficiency.

“Humanity is very dependent on carbon-containing fuel as an energy source. It plays the key role in transportation and energy engineering,” explains Maria Grabchenko, head of the project and early-career scientist at TSU Faculty of Chemistry. “But the more companies and enterprises rely on it, the more the danger of smog, acid rains, ozone layer depletion, and so on. The majority of modern-day catalysts cannot solve these global-scale issues due to high costs of metals and low stability of catalysts in real-life scenarios.”

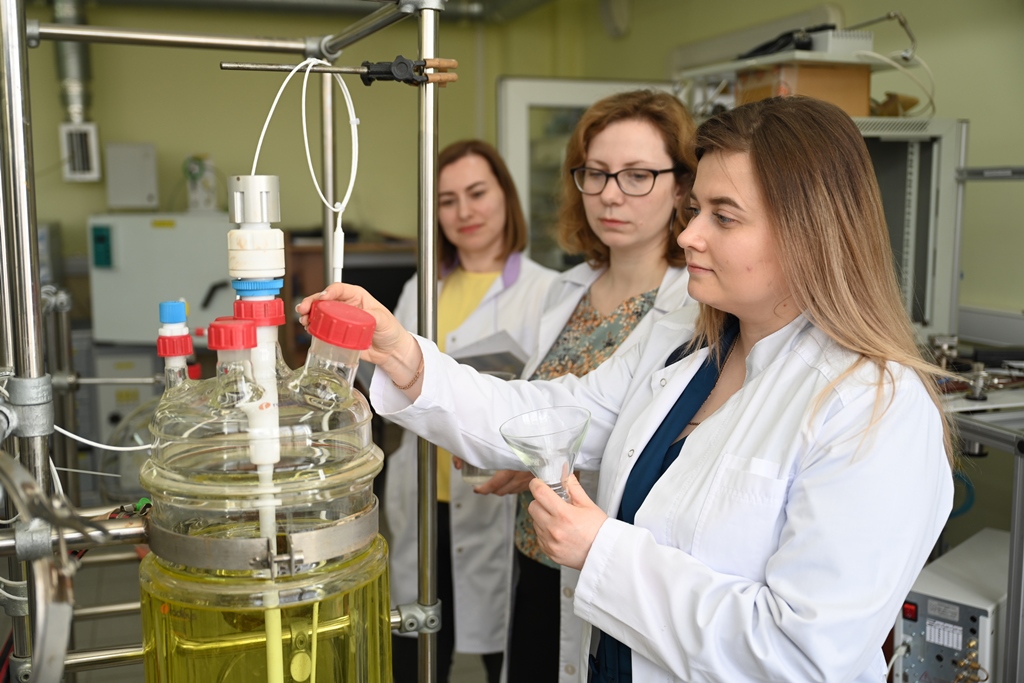

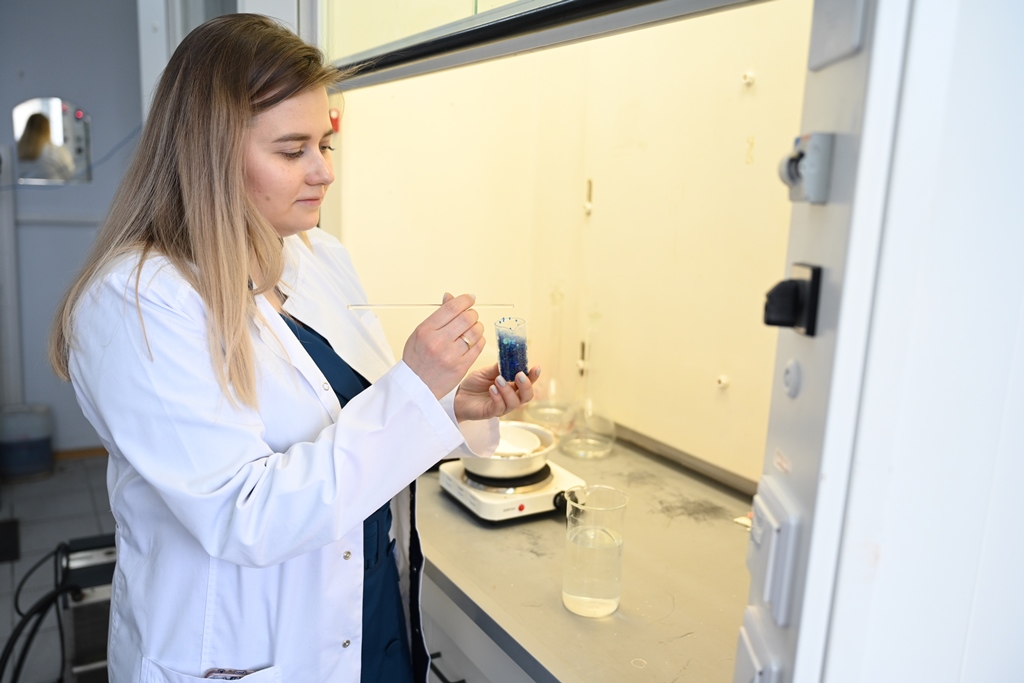

To solve such challenges, TSU chemists are developing new catalytic materials. Their composition will heavily rely on cerium oxide, manganese, zirconium, and tin. Biometallic particles Ag-Cu will be the active component, with high oxidizing ability. The chemists plan to achieve the required functional properties at the catalyst synthesis stage.

The team aims to create a catalyst that is highly efficient, stable, and resistant to sintering and catalytic poisoning. One aspect that makes creating such a catalyst complicated is that such materials have to have high temperatures to work. But before an engine has warmed up, soot is already being released, which is what makes the problem of cold start relevant. Another challenge is lowering the temperature at which soot could be decomposed at industrial sites, where fuel burning is necessary to the production cycle.

“To lower the temperature of soot decomposition we plan to rely on the high oxidizing properties that are provided by the active component and the catalyst carrier itself,” says Maria Grabchenko. “The catalyst will oxidize the soot particles and carbon monoxide gas into harmless compounds—carbon dioxide and water. The new materials are expected to be more efficient, and their costs are a definite advantage: Silver is significantly cheaper than platinum.”

New catalytic materials are also expected to leave no negative effect on the environment and be usable after the temperature treatment. TSU-developed catalysts could be used in filters installed in vehicles and industrial buildings, as well as in ordinary closed spaces.

New materials and technologies for ensuring technological, environmental, and digital safety are being developed within the key research initiatives promoted by TSU as part of the project Safety Technologies being implemented within the federal program Priority 2030.